Pulley bearing and its application

2022-05-25 Author:Luoyang Best Precision Machinery Manufacturing Co., Ltd. Click:1494

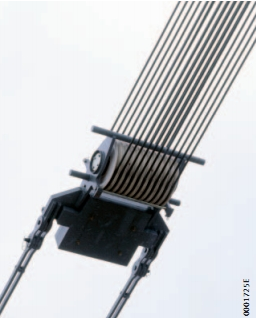

Application of pulley bearing sl04 on Liebherr crawler crane lr11350

Liebherr crawler crane LR 11350 is one of the largest truss jib cranes in the world at present. Figure 1. At the same time, it is also one of the world's * * * high crawler cranes. The total height of truss boom is 228 m and the height of hook is 223 M. In November 2006, two 5MW offshore wind turbine prototypes were erected at a test point in kuxsport, Germany. The crawler crane LR 11350 successfully completed this task.

Thanks to the modular design, the crawler crane can be divided into different parts. These disassembled parts can be transported to the installation site through small transportation equipment, where they can be reassembled quickly and easily.

The crawler crane LR 11350 can be installed with various boom systems and lifting systems. Under heavy load and various weather conditions, the pulley bearing sl04 installed on the crawler crane can drive reliably.

The industrial department of Schaeffler Group provides each Liebherr crawler crane with more than 100 sets of sl04 series cylindrical roller bearings for pulley support.

technical data

■ 6-cylinder supercharged diesel engine, 641 kw

■ driving speed: 0 – 1.08 km / h

■ * * * heavy load at high lifting height:

1350 t * * * large lifting height at 12 m

■ * * * large lifting torque: 22 748 t ● M

■ main boom: 30 m – 150 m

■ jib: 12 m – 114 M

■ super lift boom: 42 m

■ super lift counterweight: 600 t

■ total counterweight: 900 t.

Pulley application

Pulley is the slewing and guiding unit in crawler crane and truck crane, as shown in Figure 2. At present, pulleys are mainly made of plastic, such as cast polyamide.

The unique advantages of plastics are reflected in the following points:

■ make the cable moderately elastic

■ wear resistance

■ good toughness at low temperature

■ good resistance to lubricant and climate corrosion

Plastic pulley has higher requirements for bearings. Plastic pulley and bearing steel have different coefficient of thermal expansion, which requires accurate consideration and careful selection of installation fit and internal clearance.

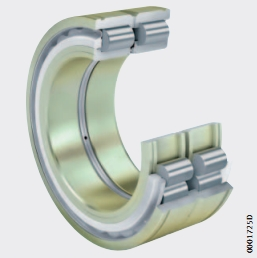

Ina pulley bearing

In order to minimize the maintenance of the pulley, the pulley bearing arrangement must meet the following requirements:

■ long life

■ effective sealing in the whole process

■ good relubrication design

■ corrosion protection.

When selecting bearings, good weather corrosion resistance, low maintenance, convenient installation and high bearing capacity must be considered.

Application of Schaeffler Group products in crawler crane

The bearing installed in the crawler crane shall withstand continuous high load and temperature fluctuation, with corotect ® The coated cylindrical roller bearing provides an optimized bearing arrangement for the pulley.

Pulley bearing sl04260-pp-rr-c5-l091 is applied to crawler crane LR 11350. High strength sealing rings are installed on both sides and pre filled with corrosion-resistant high-performance grease. Selecting the correct installation fit is also conducive to the reliable operation of the bearing, as shown in Figure 3.

Special coating

Corrotect ® It is a very thin electrostatic zinc iron coating without Cr (VI) element to protect the rolling bearing from corrosion. Thanks to this coating, rust can be prevented under the sealing lip, early wear of the sealing lip can be avoided, and external pollution and water cannot penetrate into the bearing.