Transformation and development trend of backup roll structure of straightener

2022-05-25 Author:Luoyang Best Precision Machinery Manufacturing Co., Ltd. Click:1445

The defects of rolled pieces in the process of rolling, heat treatment, cooling and transportation are often corrected by straighteners in metallurgical processing plants. Straightening has become an essential process in cold rolling, hot rolling and other rolling processes. The straightener can not only correct the shape and position defects of rolled pieces, but also break scales, resist wrinkles and improve the mechanical properties of rolled products. As users have higher and higher requirements for the quality of rolled pieces, especially cold-rolled and hot-rolled plates, how to improve the mechanical properties and machining accuracy of the straightener itself, prolong the maintenance cycle and reduce the production cost has also become the research content of metallurgical machinery.

1 Structure of backup roll of straightener

Taking the hot rolling straightener as an example, its backup roll is composed of multiple rolls, and the upper and lower backup rolls are staggered with the work roll. The hot-rolled plate passes between two rows of work rolls, which are corrected in the longitudinal and transverse directions. In order to ensure the straightening quality, the work roll of the straightener adopts a single roll shape with small diameter and easy to bend, while the backup roll adopts the axial sectional form with monomer adjustment to control the bending deflection of the work roll. The basic structure of the upper and lower backup rollers of the original straightener is the same, and the double support structure of roll neck bearing is adopted. Considering the factors that facilitate the removal of iron oxide powder and other impurities in the straightening process, the working surface of the lower backup roller is a spiral groove, and when installed, the left and right front and back are configured in a staggered spiral direction in the same group and between groups. The structure has the following problems: (1) the bearing capacity is weak and the service life is short. (2) the bearing has poor sealing performance and insufficient lubrication conditions. (3) the motion accuracy of backup roll is poor.

2. Structure of backup roll of new straightener

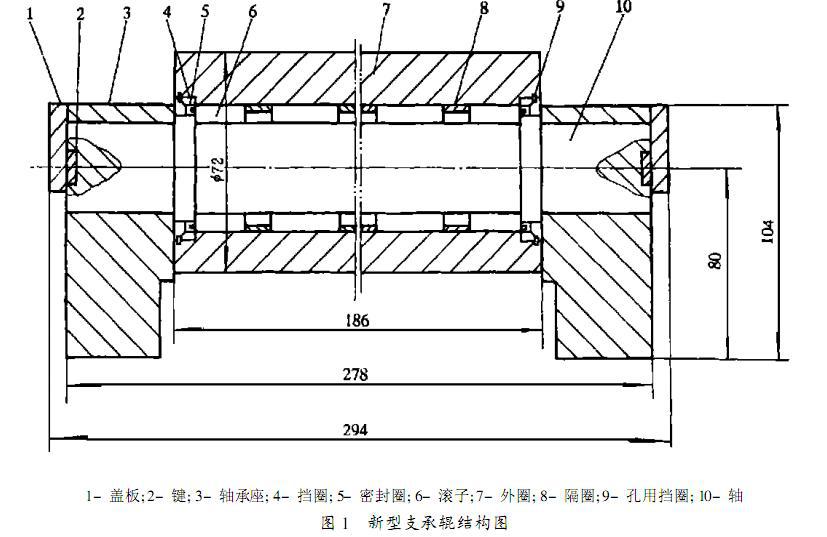

The structure of the backup roll of the new straightener (Fig. 1) changes the original roll neck support into a fixed support rolling bearing unit, and its structural characteristics are as follows.

2.1 the bearing capacity of backup roll is improved

Taking the backup roll of the straightener (the journal support bearing is the double row cylindrical roller bearing sl185007) as an example, the traditional double support structure is changed to the drum type structure. The backup roll is taken as a rolling bearing unit, that is, the backup roll shaft is taken as the inner ring of the bearing, the roll body of the backup roll is taken as the outer ring of the bearing, the rolling body is installed between the roll shaft and the roll, and the two ends of the backup roll are directly fixed by the wallboard.

2.2 improve the sealing performance of the bearing

The bearing rolling element of the backup roller of the new structure straightener is in the roller, and the inner framework double lip seal is adopted on both sides, which greatly improves the sealing performance of the bearing and effectively prevents the iron oxide scale from entering the rolling element. Practice has proved that after the disassembly and inspection of the backup roller of the new structure, almost no iron oxide scale and sundries enter the working surface of the rolling element, inner raceway and outer raceway, The phenomenon of abrasive wear no longer occurs.

2.3 effectively improve the motion accuracy of the backup roll itself

Because the back-up roll and wallboard are supported without rolling, the motion accuracy of the back-up roll only depends on the processing accuracy of the roller, roll shaft and rolling body. Therefore, there are few factors affecting the cumulative error of motion accuracy.

The motion accuracy of the backup roll of the new structure straightener is 0 008mm (the measured motion accuracy is 0.003 mm).

2.4 obtained by axial movement***

In the process of straightening, the straightener often produces axial force, resulting in axial movement of the bearing and the whole backup roll. The axial displacement of backup roll is controlled within 0.65mm by grinding axial retaining ring, which plays a positive role in prolonging the service life of seal and bearing.

3 development trend of backup roll structure of straightener abroad

With the development of steel rolling industry, users have higher and higher requirements for the shape and position tolerance and surface quality of rolled pieces. Therefore, the research on the supporting structure of straightener in foreign advanced countries is more and more in-depth, and mature experience has been obtained. NSK bearing company of Japan has taken the segmented backup roll as one of the bearing units. Its structural features are as follows:

3.1 sealing structure with low torque and high reliability

The backup roll is driven by the friction of the work roll. If the torque of the backup roll itself is too large, it will slide between the backup roll and the work roll, causing roughness and scratch on the roll surface, which will affect the surface quality of the rolled piece. Therefore, under the premise of preventing external sundries and calendering liquid from entering the bearing, high reliability labyrinth seal and side double seal are adopted, It can ensure that the backup roll rotates under low torque and has reliable sealing performance.

3.2 increase the strength and rigidity of backup roll

Under the condition that the size of the roll allows, the new backup roll adopts needle roller and multiple rows of cylindrical rollers as radial support and single row ball bearing as axial positioning, which is conducive to the improvement of the strength and rigidity of the backup roll.

3.3 adopt high-quality roll materials

Due to the harsh working conditions of the backup roll, the bearing surface is often corroded and worn. Therefore, the new backup roll of NSK bearing company in Japan adopts AWS corrosion-resistant steel. After special heat treatment, the surface hardness and wear resistance of the backup roll are significantly improved.

3.4 improve the accuracy of backup roll and improve the quality of roll surface

Due to the change of the traditional double support form, the accuracy of the backup roll has been greatly improved. NSK company especially emphasizes the mutual height difference of the backup roll and its own motion accuracy. At the same time, in order to effectively protect the surface of the work roll, it puts forward higher requirements for the surface roughness of the backup roll. At the same time, the arc correction is adopted for the surface edge of the backup roll to eliminate the edge pressure and make the load distribution more uniform and reasonable.

Lyzj company has designed a new type of backup roll based on the design structure of foreign backup roll, which has reached the international leading level. Now it has been supplied to the foreign host market in batch. At the same time, it provides OEM services, which will greatly reduce the production cost.

- Next:Nothing